Hello from Djibouti.

Our port engine is still leaking oil. We had a bolt delivered to a Yanmar engine mechanic to see if they could find an identical one to replace our missing bolt. It took six hours to deliver the bolt to the mechanic and another 22 hours to have three (two of which were the right size) delivered back to our boat.

Unfortunately, adding the missing bolt did not resolve the problem.

A mechanic was supposed to look at the engine yesterday but there was apparently a pressing need from another boat so we never saw the mechanic. Yet another mechanic is supposed to come to the boat this morning. It is 10:08 a.m. as I write this sentence. We think the engine might need to be pulled from the engine compartment before it can be repaired. That gets much more complicated because they have to figure out if they can work on it on our sugar scoop (very little room) or have to take it to land. I have a feeling we are looking at several more days in Djibouti.

Which leads me to my next tale – that of filling our tanks with water. I want to compare two experiences, as it is of interest to me and hopefully to you.

When we were in Oman, you will recall that we were in berth 26, which meant that we were tied to a cement wall. When we needed water, we simply notified our agent, who arranged to have a hose brought to the water spigot located right by our boat. We turned on the spigot, filled our tanks, and washed our boat. The cost was $20 (maybe $30?) USD. We could use the spigot for small amounts of water at other times as well, such as to fill a bucket or two. Easy peasy. Oh, and we could do so during the daytime.

In Djibouti, we again reached out to our agent, who told us we could go to the dock at 1800 hours. For those who don’t know, 1800 hours is 6:00 p.m. For those who also don’t know, it is dark at 1800 hours, or shortly thereafter, in Djibouti which meant that we would be pulling up anchor and traveling to the dock under the cover of night. That is the first difference.

The second difference is that we needed to wait for a spot to open on the dock. Thankfully, two very large ships that were rafted up offered to let us go ahead of them. I cannot imagine how long it would have taken them to fill up with water, so we were and are eternally grateful. In any event, we had to wait for them to back up so we could access the dock.

A third difference: While we were waiting to get to the dock, a Coast Guard boat came by to check on us. Boats cannot come to the dock without permission and they can only come to the dock at 1800 hours. Our agent convinced them that we were legit, so they left.

The fourth difference was the docking experience. I had already tied our four fenders and two dock lines to the port side, so we just needed to get near enough to the dock to toss the lines to the guys on the dock and adjust the fenders as needed to protect the boat. The wind blew us to the dock and all seemed to be going well. That is when we saw the very large cylinder-shaped cement – I am just going to call it a monstrosity – located just off the surface of the water near our stern. Thankfully one fender was just low enough to “fend it off” and we quickly moved the other fender next to it and lowered both to better protect the boat. The bow end of the boat was a completely different story. At that end, there were no cement structures near the water. The only part of the dock that could damage the boat was higher up. Luckily, one of the fenders I had placed near the bow protected it.

Fifth difference: Once we were safely secured to the dock, Michael and Ahssan (our agent) had to take our documents to the port authority because they require paper documents, not electronic. That took about 15 minutes. I stayed on the boat and played Sudoku while sitting on the trampoline. One of the men who stayed near the boat tried to make conversation with me but we quickly realized that we did not speak the same language. Several other men smiled and waved as they walked by. The dock was rather busy. I have yet to see a female on a dock in either Oman or Djibouti.

Okay, so they came back to the boat. We then waited approximately 30 more minutes (I don’t really know how long each gap was as I wasn’t timing) for someone to bring the hose that would deliver the water. I made our dinner while we were waiting since it was clear that we were going to get back to our anchorage well after dinner time. (The entire experience from pulling up anchor to anchoring again was about two hours.)

Once the hose was hooked up, filling the tanks took a matter of minutes. Michael also hosed off the top of the boat for good measure in an attempt to rid it of some of the bird poop.

Here’s the most exciting part of the story and the sixth difference: leaving the dock. Remember that we have one working engine and it is on the starboard side, not in the middle. Monohulls also have only one engine but it is in the middle. So, we were handicapped by having only one off-center engine . . . with prop walk. In addition, we had a very big boat behind us now and a very sturdy and very hard dock to the left of us and another very sturdy and hard side of the dock about 8-10 meters in front of us. We also had a boat to our starboard side, perpendicular to our boat. In short, a very tight spot.

Thankfully, Ahssan and I were on the boat with fenders and our arms and legs. There were also three men on the dock to assist. We started off okay by pushing away from the dock but immediately realized that our maneuverability was perhaps even worse than expected. Also, the wind wanted to push us back to the dock (cement, hard, big, etc.), and the prop walk assisted the wind. In short, getting away from the dock proved to be problematic. Somehow, with enough pushing, motoring, and steering, we made some progress, but the main progress was forward motion with just a tad to starboard. Michael was trying everything possible to get the boat to move the way he wanted it to move. Forwards, backwards, rev the engine, put it in neutral, move the wheel, etc. At one point, the stern almost ran into the part of the dock that had originally been in front of us. Again, bodies, fenders, pushing, etc. As the boat finally agreed to turn to starboard away from the dock we ran the risk of running into the boat that had been perpendicular to us at the intersecting dock. We missed it by about a foot.

Once truly clear of the dock(s), we motored between both moving and anchored boats back to our anchorage. Michael had placed a waypoint on our chart (a VERY good idea) to help us find it in the dark. We made it safely, of course, or I wouldn’t be writing this.

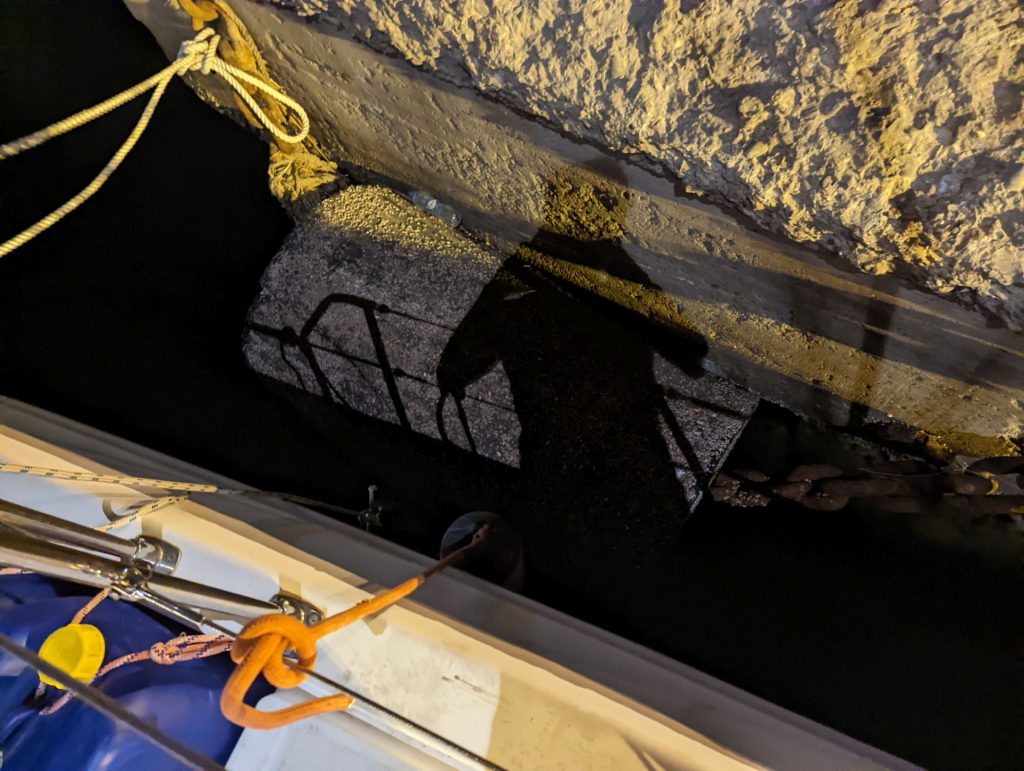

The other thing of mild interest was the condition of our anchor chain as we raised the anchor to go to the dock. The seabed here is clearly very muddy, and much of the mud decided to adhere to the anchor rode.

So that is pretty much yesterday’s exciting story. Pictures here:

Things are not sounding good. Hopefully the mechanic can figure it out.

Yeah it won’t happen here. We are not happy with the condition of the boat, as it was not what Sunsail/Moorings should have delivered.

Oh my, I sure hope you can get that engine fixed in a timely fashion. I am thinking you will be pretty happy when you can leave Djibouti! Interesting reading about your experience and the patience and perseverance to get the things you need- like water!

Take care!

Jacki

It turns out we will not be able to get our engine repaired in Djibouti. We will have to go up the Red Sea with one working engine. We are quite upset with Sunsail/Moorings in the Seychelles. They did not provide us with a working boat even though they had four months to complete repairs. We would not recommend anyone buy a boat from them.

But we persist.